Seminar Throwback: When To Repair Vs Replace Your HVAC Unit

At Blue Ridge Heating & Air, we’re on a mission to educate homeowners so they can make smart, confident decisions about their comfort systems, not panic during a heat wave or freeze.

If you missed our June seminar, here’s a full recap with expert insights, maintenance tips, and quotes straight from the conversation.

How Long Should an HVAC System Last?

System lifespan depends on how well it’s maintained and the type of equipment:

|

System Type |

Average R22 Lifespan* |

Average 410A Lifespan* |

|

Heat Pumps |

10-15 Years |

15-20 Years |

|

Air Conditioners |

10-15 Years |

15-20 Years |

|

Mini-Splits |

12-16 Years |

15-20 Years |

|

Furnaces (paired with AC) |

10-15 Years |

15-30 Years |

*actual results may vary depending on climate, usage, maintenance, etc.

Pete explained,

“R22 systems are obsolete now. They’re very costly to repair and hard to service. Many companies, including us, don’t even work on R22 any longer.”

By comparison, R410A systems still have years of serviceability left, and new refrigerants like R-454B are arriving with improved environmental impact.

What Are the Warning Signs of System Failure?

You shouldn’t wait for a total breakdown. Keep an eye out for any of these red flags:

- ✅ Constant repairs

- ✅ Rising energy bills

- ✅ Uneven temperatures

- ✅ Loud or unusual noises

- ✅ Short cycling (turning on/off quickly)

- ✅ Signs of age or corrosion

One major red flag? Compressor failure. Brian noted, “It’s one of the most expensive repairs, and not worth it on older units. Replacing a compressor could run about $4,000, while a new system might cost $10,000–$12,000 and last you another 15 years.”

Pete summed it up perfectly:

“If the thing looks like it came over on the Ark, or the nameplate is so faded you can’t read it: it might be time.”

Repair vs Replace: When Replacement Makes More Sense

Beyond repair costs, new systems come with significant efficiency benefits. “Modern SEER2-rated systems cool more efficiently, especially in high heat,” Pete explained. Plus, they’re quieter, cleaner, and compatible with smarter controls and zoning technology.

And don’t forget incentives. Depending on your utility provider (like Duke or Lawrence Electric), rebates and tax credits can reduce the cost of upgrading your system.

Maintenance: The Secret to System Longevity

Proper maintenance can add years to your system’s life. According to the Department of Energy, poorly maintained systems lose around 5% of efficiency each year. That means after a decade, your system could be operating at half its original efficiency.

“Filters are your biggest issue. Change them every 30 days if they’re one-inch filters.” – Brian

Maintenance benefits:

- Boost airflow by 10–46%

- Reduce energy use

- Prevent coil corrosion and blower strain

- Extend system life

- Avoid breakdowns in peak season

Tips to Make Your System Last Longer

- Schedule professional tune-ups twice per year

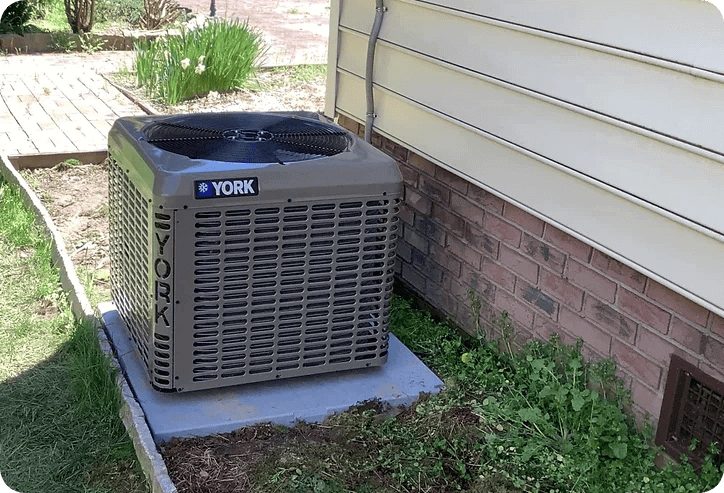

- Keep 2–3 feet of clearance around outdoor units

- Replace filters every 1–3 months

- Use a programmable thermostat

- Watch for unusual smells or sounds

“Think of it like your car. If you don’t change your oil, it breaks down sooner. Same goes for your HVAC. Routine cleanings, especially inside the cabinets, can boost airflow by up to 46%.” – Pete

Need help? Our Blue Ridge Comfort Plan includes two annual tune-ups, priority scheduling, repair discounts, and more to protect your HVAC investment.

Crawlspaces, Moisture, and the Hidden Threats

Many systems in our region are installed in crawlspaces, and that’s where moisture becomes a major issue. “Moisture corrodes controls and wiring,” Brian explained. “If it’s swampy under your house, your system’s life will be shorter.”

Humidity control, in particular, has a huge effect on comfort and energy use. “It’s easier to condition dry air than humid air,” one guest said, highlighting the partnership between HVAC performance and crawlspace encapsulation.

Final Thoughts

Whether you’re replacing a failing system or just trying to get more life out of the one you have, remember that proactive care makes a difference.

As Pete said in closing, “Even if your system’s in good shape now, routine care is the number one way to keep it that way.” That includes changing filters, keeping outdoor units clear, and listening for unusual noises.

Heating and Cooling Issues? Click Here!

📞 Ready to feel the difference in your own home?

Schedule a free comfort consultation with us today. No pressure, no pushy sales tactics. Just good folks helping you stay informed and save money.

✅ Get a quote

✅ Get it done right

✅ Sleep better

HVAC Warning Signs Seminar: Transcript

Pete: All right, so here we go. Blue Ridge Heating and Air: When to replace your system. “An ounce of prevention is worth a pound of cure.” Baily Shannon, who’s going to get the chicken, is the creator of this, and he worked in collaboration with Brian, who’s the brains of the outfit. And then you got me proof that there are equal opportunity employers here. All right.

So why does it matter and what you’ll learn? Why it matters is 90 degree plus days are just weeks away. This is when most heating and air conditioning systems fail and the fast decisions cost you the most. Did you know the HVAC breakdowns peak during the first major heat wave of the year? Units are on the edge often give out under the pressure. When that really hot heat wave comes in, people start cranking their ACs up to get them going and it’s just blowing lukewarm or hot air and that’s when the phone starts ringing off the hook. How long should you, the questions that we’re going to find out are how long should an HVAC system last, key warning signs before failure. when it makes more sense to repair versus replace, especially with older refrigerant 22 systems, and what new energy efficient systems can save you, and some good maintenance habits that can add years of life to your heating and air system.

Lifespan and realities: R22 versus 410A, what you need to know. R22 systems are obsolete now. They’re very costly to repair and very hard to service just because parts and refrigerants are really hard to get. Many companies don’t even company R22 any longer, including us. 410A, still available, but it is being phased down over the next 15 years, which generally corresponds with the lifespan of a system. So if you put in a new system today with 410A, by the time it wears out, you know, that’ll be about when 410A is not available anymore. So average lifespan of our R22 systems, 10 to 15 years and with some good maintenance and repairs and good conditions, they could last you longer. 410A system, 15 to 20 years and with the same conditions, they can last longer as well. So let’s see here, heat pumps, furnaces, mini splits and air conditioners is what we’re talking about today.

Any questions? Up here in the corner’s while you never drink and mow.

Guest 1: What happened?

Pete: Never drink and mow.

Brian: I’ve seen a bear tear our unit off to get to the ants underneath the pad too.

1: Oh wow. That sounds like the North Carolina thing.

Brian: Oh yeah.

Guest 2: This might be a dumb question. The type of refrigerant, is that more than just the actual liquid refrigerant or gas inside the compressor or is it a whole separate type of compressor and coil or is it just the actual…?

Brian: It’s the compressor that has to be designed to pump that particular refrigerant. And then there’s other controls on that that match up with that refrigerant because it changes temperatures and pressures at different points.

2: So if you’ve got an R22 old unit, you can’t just, just because you can’t source R22, can’t come pump for 10A.

Brian: No, sir.

2: Got it.

Brian: The newer refrigerants are more compact or closer in design with pressures and temperatures where they are 22 the pressures like 30 to 50% lower. It was really nice to work with compared to the 410 a and the newer refrigerants

Pete: All right expected life span by system type and the power of maintaining your system so average lifespan by system type air conditioners 15 to 20 years, furnaces 15 to 30 years, heat pumps 10 to 15 years, and mini splits can last 15 to 20 years. Mini splits are heat pumps pretty much in essence. And that is sourced from the HVAC guide guides and standard plumbing in hvac.com.

So why does maintenance matter? So every year they lose about 5% of efficiency without proper maintenance. In 10 years you’ve lost about 50 percent of its efficiency. If you hadn’t maintained it and a lot of people are like, it’s working I don’t need to do anything with it. But in all actuality, you know, they do that with their cars too. And that’s why you them sitting on the side of the road. But if you do your oil changes every 5,000 miles and change the filters and all, then they last you a whole lot longer and give you better service. So routine cleanings can boost air flow by about 10 to 46 percent. And we’re talking about cleaning, we’re talking about inside the cabinets, right?

Brian: Cabinets, coils, and filters. Filters are your biggest issues.

Carey: Is that recommended every year?

Brian: No, filters should be changed every 30 days. The one inch filters, then they have the immediate air filters where they can last up to a year.

Carey: Okay. So you’re talking about the routine cleaning?

Brian: Once a year.

Pete: Fan or blower energy use drops up to 60% after cleaning. Erosion and corrosion can reduce efficiency by 15 to 20% if ignored. Maintenance helps extend the lifespan and reduce costly breakdowns. So just do the maintenance on your units and they’ll last you longer. I’m sure with you guys’ solutions, there’s some maintenance that needs to be done from time, especially on the salt pumps and de-hues.

So when’s it time to replace that thing? If you’re having to do constant repairs, constantly break, constant breakdowns, especially in the peak season. So when it starts getting really hot and you start having a lot of failures, hey, let’s start thinking about replacing that thing. Or when you hit that first cold wave and you got a heat pump and it’s not warming you up, it’s time to look into doing something else. Uneven heating and cooling, just so if you got hot or cold spots in your house. Your system might not be keeping up, so it would be time to replace it then. If your energy bills are shooting through the roof, last year it was 200, this year even though Duke went up. still shouldn’t be doubled. So if your energy bills are really high, it’s time to replace it. If you hear that unit being really loud, making some unusual noise, time to replace it because there’s some internal wear going on there. A lot of frequent stops if it’s on and off a lot. That’s a sign. And age, if the thing looks like it came over on the arc. My rule is if you look at the nameplate and you can’t read it because the words are all faded off, it’s time to replace it. In our 22 systems, they’re obsolete and it’s time to get rid of them. And if they’re not failing, it’s just a matter of when.

So when does replacement beat repair? Compressor failures are often very expensive if the compressor fails. Especially on an older unit, it’s just not worth the repair in comparison to what it would cost to replace it. If it’s an R22 system, if anything shuts it down, we pretty much say, it’s time to get a new one. The cost curve doesn’t lie, repairs get more frequent and as they age and you start getting nickel and dimed every year, especially after 12 years, it’s time to start thinking “replacement”. And a new system, you know, like say a repair for a replacement of compressor on a two ton, two and a half ton would be what about?

Brian: About $4,000.

Pete: About $4,000. A new system can cost you around 10 to 12 on the lower end. So a new system may cost you more upfront, then, you know, for the next 15 years, you’re not having to worry about it. just…

Brian: And with that, people don’t realize the compressor doesn’t cost that much, but the labor intensity, you have to remove the refrigerant, you have to unsolder and re-solder that new compressor in, nitrogen test, vacuum, and then add refrigerant back into it. We’re not putting your old refrigerant back in. We’re going to give you a new fresh out of the jug. So… There’s where the cost is. I mean, it’s four to five hours to change out a compressor. So it’s very time consuming.

Pete: That’s for a good tech.

Brian: Yeah. And there’s sometimes you have to climb in there with it to braze it. And it’s just you’re sitting on top of the compressor while you’re trying to braze it. So it’s kind of interesting.

Pete: Questions? All right, moving along rapidly. So if replacement ever becomes necessary, here’s what has changed.

2: I have a question. For, I guess on either AC furnace or heat pump, do you guys find that the compressor or some type of issue with coils or refrigerant leak or whatever, is that normally the most common first issue to go compared to some kind of electrical thing or lower motor or just something unrelated?

Brian: I would say the compressor goes bad because something caused it. The filters are stopped up, the coils are stopped up, it run harder. But you can have power surges, lightning, or things like that that can really take out a system. So but coil leaks is your biggest thing and I think because it’s so slow you don’t realize it like when you go from say January/February where it’s real cold. You’re using it well, I’m not gonna use it until May now because it’s not hot enough and that’s where it started to leak way back when and then all of a sudden you turn on it’s not keeping up. So we don’t notice it, we’re not paying attention to it, because if I’m not comfortable, I’m not paying attention to it. That’s when you really notice it, I think, is when “I’m starting to get hot, I’m uncomfortable”. Let me check the thermostat, that’s the first place we go. It’s reading temperature, so it must be okay, but there’s actually something going on. And then when it gets real hot, then we’re making phone calls and everybody else is in the same boat.

2: Makes sense.

Pete: So here’s what’s changed. So between the old R22 systems and old 410 systems even now, they’re more efficient now than they were, then they get better every year. So the modern Seer 2 rated systems cool more efficiently, especially in the high heat. There’s smarter controls as far as uh computer boards and as well as the thermostats. Those things can do everything but change the baby’s diapers. Now I mean they get really, we can get them as complicated as you really want them to be, but you know the KISS method is best when it comes to this right. “Keep It Simple, Silly”. Programmable thermostats really help out with efficiency. That’s something that’s not extremely new, but it could be new to your system if you didn’t have that. They’re cleaner and more quiet in operation. Some of them, I’ve heard people say they put their ear to it because they don’t know that it’s working, but they’re comfortable. So that’s really a cool thing to have and so um also today’s systems are using a more advanced filtration and variable speed fans to reduce allergens and noise. There’s also tax incentives that you can get tax credits for getting a more efficient system and depending on who your power company is you can get some really good rebates. Duke has the best, Lawrence Electric, and then I don’t really know, does anybody else have them besides Duke and Lawrence?

Brian: That’s all I know.

Pete: Right, so you know if you got somebody else you can check with your power company and see if they offer any kind of…

Brian: We have Duke and Hayward up in Asheville and that part of the county and even across the street from the shop in a development, half the development has Duke and half has Hayward. So you can be across the street and you can be different.

Carey: That’s how my neighborhood is either like Blue Ridge or Duke. That’s right here.

Pete: Yeah, Pelham Falls?

Carey: We got a new place. Is Pelham Falls the same way?

Pete: Oh, I was thinking Pelham Falls. Half of that neighborhood is on Duke and the other half is Lawrence.

Carey: Lots of fun when the power goes off and half the neighborhood is really angry.

Pete: Yeah. So how do we make the system that you have last longer? Well, tune-ups, just like on your car, annual professional inspections help catch problems early and improve efficiency. Regular tune-ups can improve your system efficiency by up to 30% according to the US Department of Energy. If you replace your filters often, that helps. Dirty filters restrict air flow and make your system work harder. So check monthly and replace every one to three months, depending on how dusty your house can get. Pets and smokers and what you cook and things like that can also affect how dirty the filters are. I had, somebody was talking about how their wife burns a certain candle and it discolors the filter because she burns a lot of candles in the house. So avoid extreme temperature swings by putting a smarter programmable thermostat in to maintain comfort and energy.

Also, keep your outdoor units clear. Make sure there’s two to three feet of space around your outdoor unit. Clear away leaves, plants and debris regularly. So how many times do we go out to check one or service it and there’s all kind of stuff just growed up all around it. You need a weed eater or a flame thrower to get around it. Listen to your system when you hear it turn on and off. Do you have any funny noises that you didn’t hear before? Any smells, burning smells? These are all warning signs that it’s time to get this thing looked at and maybe replaced. So a bonus stat that Baily gives us here, “proper maintenance can reduce the risk of major breakdowns by up to 95%”.

Brian: That was from ASHRAE. So I don’t know how familiar you are with them. They’re just a government, not a government agency, but an agency that works on monitoring what the systems are doing. And they do so much more than I’m saying, but there’s a lot to them. They’ve been around for ages.

Pete: So make maintenance easy with a comfort plan, and if you don’t have one, we’ve got them for you. So even if your system’s in good shape now, routine care is the number one way to keep it that way. So in ours, you get two system tune-ups a year. One, we like to do it in the spring just before summer, and then we like to come back in the fall and check it just before the cold of winter. When you’re on our maintenance plan, you get priority scheduling. So if you call and say, hey, I’ve got a problem, when we see you’re on the maintenance plan, you get priority. It’s like you fast pass it, Dollywood or Carowinds. So you skip the line. You get repair discounts on any kind of repair, indoor air quality, and you get system longevity support, and it’ll protect your investment.

So thanks for joining us. So hopefully what you’ve learned today is how long a system typically lasts. 10 to 15, 20 years. What’s the warning signs that your system might be near in its last days? The difference between refrigerant 22 and 410A systems. What a modern system can do for you and how to maintain what you’re new one or what you already have. We’re always here to help. So if you want to talk about what you’ve got at home or some warning signs that you may be seeing or what’s changed?

Guest 3: How much of y’all’s maintenance plans taken off? Is that, I mean, does that-

Brian: What do you mean?

3: Has that really increased over the last few years when you see more and homeowners going that route of saying, hey, I want someone to come out here?

Brian: We have a lot of people. A of people. I don’t know the numbers, it’s things that you don’t see. You know.

Pete: And we’ve got it by the year. It’s $239 person for the first system, $199 for the second.

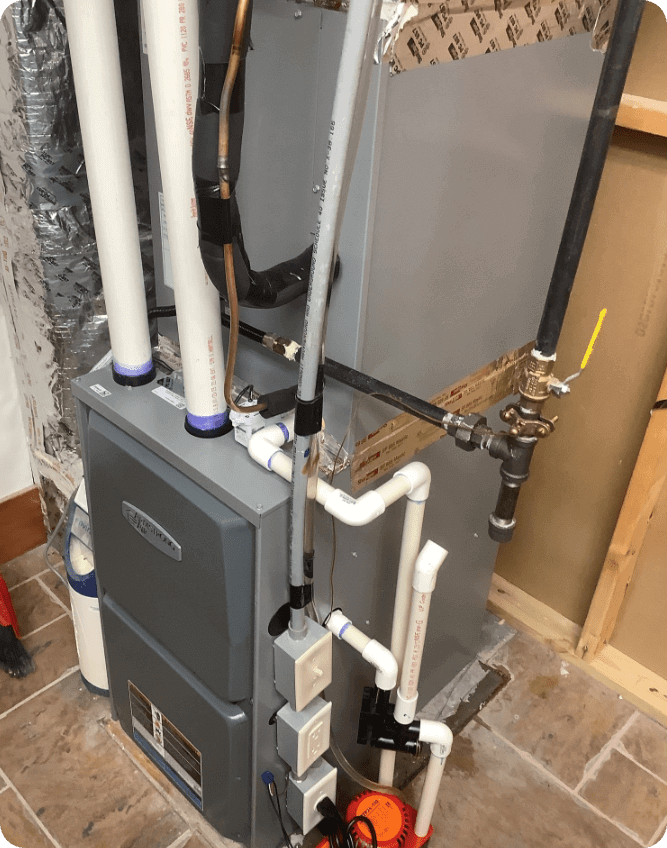

Brian: And then we also inspect the dehumidifiers and the humidifiers, or other systems that you have in that house, like a ductless system. So, but filters is the biggest thing. If, I believe you had a question about the crawl space that you sent over, if the filters are stopped up, it’s going to pull air from someplace. That motor is still going to try to move as much air as possible. So as you look at this furnace here, you see we have little holes and if the duct work is not sealed up properly, it’s going to pull it through these holes or through the doors. So you open the door and you see dust all around the doors. Even if you find that you take the filter out and you see dust around the outside of the framing, you know that filter is staying in there too long. There’s some things to look for.

2: Our education to homeowners, what type of filter would you recommend? You can get the really thick allergen proof ones or the really thin. What’s your recommendation?

Brian: I’d say around a Merv 11 to 13. If you get into a Merv 16 and you have any stoppage in there, you’re really going to choke down the system. Because a of times the filters are a second thought. “My husband’s in charge of that.” Well, he’s not doing a very good job. He really can’t say that, but the filters are all stopped up and you get to the houses, and that’s where the maintenance guys really catch on to that.

Carey: Okay, hold on. I’m in charge of the filters. What is, when you talk about the MERV stuff, that, what you just said, is that kind of the mid-range?

Brian: Yes, it is. I believe they start down at MERV seven or eight, and then they’ll go all the way up to 18.

Carey: So we don’t need the $60 a month one that are…

Brian: That’s right. I think they stop up the unit. There’s too much restriction, because the motor’s going to pull as much air as it possibly can. What it’s designed to do, I should say. And it doesn’t build up, and because they’re so thick, they want to stop everything from getting in there. And the filter’s really to protect the equipment. It’s not to keep the dust out of the house, it’s to protect the equipment for the blower motor, the coils and things like that. So, I like the mediair filters that we’re installing, the Aprilaire mediair filters. do very little. They don’t have a whole lot of restriction. They don’t lower the static pressure in the duct work and they capture up to 92, 93 percent of the particles in the air. And I do like the pre-filters up front, like in the house because that stops all that dust and dirt from getting into the ductwork. So…

2: Obviously, what we do is inside the crawlspace basement moisture control, humidity regulation. What are talking points we can say as to how and why what we do is important? I mean, obviously the big one is humidity control and the way the house freezes and stack effect. It’s more to be efficient, easier to condition dryer air than humidity.

Brian: That’s correct.

2: Things like that. But air handlers sitting in the crawl space, what threat does to the components of the actual unit? Why is it a concern that that could be laying in a swampy crawl space? What about the air handler could go bad because…

Pete: That’s a very good question.

Brain: These will start to rust out. The corrosion on these systems, the moisture will affect the electronic controls in here. So we have control boards, we have wiring. So you’re in a swamp, as you say. Now all of a sudden that moisture is infiltrating into the system because I have vents here. I have electrical controls in here, so it’s going to deteriorate and moisture and electrical just don’t mix.

Pete: And if it gets into the system, then they’re breathing it more. Then they would… And you know, the moisture building up on the duct work deteriorates it faster.

Brian: The insulation as well. We’re putting 50 degree air through that ductwork most of the time, 45 to 50 degrees. So all that, you get that insulation starts to sweat. I know you crawled on their ductwork and it’s just your back soaking wet. That’s because of so much moisture in the crawl space, and it’s the dew point is way down, or way up. And so now you just. Yeah, it’s everything’s wet.

2: It probably has less to do with the duct insulation and the dust, the humid environment.

Brain: That’s exactly right.

2: Yeah, get, I mean, y’all will too. We get a ton of calls of sweating ducts and that we’re sweating HVAC air handlers. It’s like, well, actually that’s fine, but you’re at 84% RH down here and ponding water and all that.

Brian: I forgot about the duct work, the equipment’s sweating as well.

2: Oh yeah, I get that all the time.

Brian: Yeah. I haven’t serviced in a while, so the younger kids are doing it. So it’s just like, I’ve been there, seen it.

2: We have, we’ll have people and they have called us because they have, in this whole home improvement phase where they’ve replaced air handler, duct work, and wanted to end cap their crawl, just attacking them all angles. They still um will say after units installed in the house, they still are battling RH levels in the house of 55, 60, 65 shouldn’t be that high. And I know there’s a lot of factors. You can have leaky windows, can have, you know, chimney draft, whatever. Is it true that some modern equipment now is not as good at dehumidification in the home than some units in the past, specifically ductless mini splits, their ability to draw moisture out?

Brian: The ductless, variable speed compressors and the variable speed blower motors will handle the dehumidification better than the conventional system where it’s on and it’s off, the single stage systems. You get into the variable speeds where they can ramp up and down according to the pressure and temperatures are. That will help in dehumidification. But they are not dehumidifiers, so humidity is 100% outside, and we’re looking to maintain 50% inside the house, 40%. The air conditioner is not gonna do it. So especially up in Brevard, it’s- Yeah. So it’s 70 degrees outside. My air conditioner doesn’t need to come on, but I’m still at 100% humidity outside. So I’m looking to dehumidify. So that’s where the dehumidifier comes in. The whole house dehumidifier. you’re encapsulating. So now you’re putting a dehumidifier in the crawl space, so now you’re maintaining that humidity downstairs in the crawl or in the basement, even in the basements. So, and as you say, the chimney effect, all that’s coming upstairs one way or another.

2: Yeah. And the very technical language, uncontrolled crawl space is adding latent load to the house that you’re trying to. Is that right?

Brian: That’s a good point. That’s a very good way to say it.

Pete: I’m gonna use that.

Brian: Well, that’s a good way of saying it.

Pete: Yes, yes. It’s good to have you guys here today.

1: We appreciate your time. Thank you for having us.

Pete: Let us know when you have yours so we can come to it.

1: Yeah, pretty well. it. We’ll get some cross-training.

Pete: Well, with what you guys have and what you know, the solutions that you have, it would probably, if you advertise it, you would probably get a good response.

2: Have y’all do these, is there a cadence to this? Y’all do this monthly report earlier or something? So probably quarterly we do something like this.

Baily: We’re trying to get it to the every other month. Have it on the last week in Brevard and then the first week in Greenville.

Brian: Different subjects.

Baily: Yeah, different subjects. First one we did was the refrigerant change. That was good turnout because it was a popular topic. So we decided to keep doing that and helping out and trying to educate. So there will be more.

Carey: Is there a topic that you’d to hear about that you can think of?

2: No, I mean, what’s really interesting to us, for me, is just the intersection of y’all’s world and ours from humidity control…

3: The condition of the basement and the crawl space and what it does. What we’re doing, how it affects the expensive equipment up under the house. You know, that overlap there is interesting.

2: And you know, maybe even specifically how we can bring more value and speak, you know, confidently to why, why what we’re doing affects this, affects performance of it and everything.

Carey: Chris sent me this stat. It’s like for every 4% RH change, feels like one degree Fahrenheit. Yeah. And then for every one degree we need for a thermostat that equals 4% savings, so there is obviously the correlation to what you’re paying for your energy bill.

2: Yeah, like this will never, we’ll never be able to pinpoint this cleanly, but we’re trying to say, how can you justify $10,000 encapsulation under your house? Because it’s another piece of equipment that consumes energy to run. But it’s considering the real fuel of the house, you might be able to get by setting at one or two degrees where it doesn’t run as much and it’s not running as hard because you’ve dropped the latent load on what you’re conditioning, right? And so just trying to think through what is the, like is there a way that you could see a return on this investment by reducing energy costs or prolonging lifespan of the equipment or whatever.

Pete: And telling how much it would cost to replace all those floor joists if they all ride out.

2: That’s right.

Carey: Well, that’s kind of what got me motivated is because my floor, I can see it starting to a little bit.

Brian: Split?

Carey: And I didn’t know why until I realized there was like 92 humidity.

Brian: What do you dehumidifier do you use?

3: Santa Fe.

2: We’ll install AprilAire’s frequently at request, but primarily Santa Fe. We’re not that’s not an exclusive deal. I kind of see it as like a Ford and Chevy type thing, but great options.

Brian: I haven’t worked with the Santa Fe a whole lot and I’ve been with AprilAire for quite a long time and even Honeywell before that. So I was just curious. So yeah.

Carey: I don’t know if this could be a selling point to you, but I was talking to someone last week. His house is so humid that he hopes it’s really hot outside. so they can get a good night’s sleep because otherwise, like how it’s been in between, it’s great, it feels great outside, but his AC isn’t running and it’s so humid and hot and it’s almost the entire family isn’t sleeping well. So we’re kind of going at it like, well how much is a good night’s sleep worth it? Like, cause he will not, he doesn’t want to the trigger around the dehumidifier and doing all that, but now he’s starting to connect it.

Brian: But you’d be amazed at how the humidity really affects your comfort level. And then 5%, 10% you’re starting it’s sticking here. I’m uncomfortable. So I’m running the AC down To make it comfortable so I can sleep better as you say.

Carey: And he’s cranking it up, and then spending more money, and he’s got leaks so, he’s going to end up, it’ll take a while, but spending all the money just to be comfortable versus, having a crawlspace that I could come out and fix things.

Brian: Some of your new equipment you can raise it, I found people that were raising the temperature two or three degrees based on the old system It’s just like I had to set it at 60, 67, 68 degrees to be comfortable. Now I’m at 72. So that’s a lot.

2: For sure. Yeah. One thing we’ll never get into, probably never, is trying to do supplemental dehumitification in line with HVAC. So on supply and return, bypassing air handler, that’s, we don’t want to pretend to be experts at that when we’re not. And so that’s something. That would be a great referral to y’all, think.

Brian: We do a lot of that. We’ve got four in the shop right now, and they’re going to go out. We’re getting four. That’s shipment every time we get a load. We’re finding where you can actually put it from supply of return to supply. We’re finding it works better from return and down six feet away to return, bringing on the dehumidifier and the blower at the same time so that disperse the air better. And it seems to work better for us.

2: Does that have anything to do with the pressures of supply and return?

Brian: Yes. You have that blower from the equipment forcing air down the ductwork from the dehumidifier. So that flap kind of, you’re fighting each other.

2: Yeah, makes sense. Good deal. Thank you guys.

Brian: Thank you.

1: Thanks for the Chick-fil-A.

Brian: Yeah, you’re welcome.